Standard Paper, 90g/m2

This high quality base paper is specially developed for use in the CAD and GIS environment. The optimal drying of the media offers the possibility for maximal production. It is the economical choice for the everyday line work and area fills in monochrome and colour. Users who need an economical solution for their everyday graphic test prints will be very satisfied about the colour contrast.

Features:

Dye ink compatible, quick drying, sharp lines, smear resistant.

Applications:

CAD, GIS, economy graphic test prints.

Printing

For optimum results select the best possible print settings. Ink saturation limits can vary due to the ink drop volume and the environmental humidity. Ink saturation levels should be optimized for specific printer, ink and software combinations. Too much ink will cause paper cockle and possible head strike. Longer ink drying times will occur in higher humidity environments.

Lamination

Hot or cold laminating is possible, although cold laminates are preferred because of the better adhesion. Images must be dry before laminating. Too much ink can cause cockling which can cause problems with laminating. For mounting on a board, an encapsulating edge of 5-6mm around the image is recommended. This prevents against moisture and paper splitting because of the tension of the laminate. If the laminate is not spread evenly over the surface of the paper then this can cause curling problems.

This high quality base paper is specially developed for use in the CAD and GIS environment. The optimal drying of the media offers the possibility for maximal production. It is the economical choice for the everyday line work and area fills in monochrome and colour. Users who need an economical solution for their everyday graphic test prints will be very satisfied about the colour contrast.

Features:

Dye ink compatible, quick drying, sharp lines, smear resistant.

Applications:

CAD, GIS, economy graphic test prints.

Printing

For optimum results select the best possible print settings. Ink saturation limits can vary due to the ink drop volume and the environmental humidity. Ink saturation levels should be optimized for specific printer, ink and software combinations. Too much ink will cause paper cockle and possible head strike. Longer ink drying times will occur in higher humidity environments.

Lamination

Hot or cold laminating is possible, although cold laminates are preferred because of the better adhesion. Images must be dry before laminating. Too much ink can cause cockling which can cause problems with laminating. For mounting on a board, an encapsulating edge of 5-6mm around the image is recommended. This prevents against moisture and paper splitting because of the tension of the laminate. If the laminate is not spread evenly over the surface of the paper then this can cause curling problems.

Recommended products

Canon / MPN: 5102C002

067 Toner Cartridge 1 Pc(S)

5 439 ₴

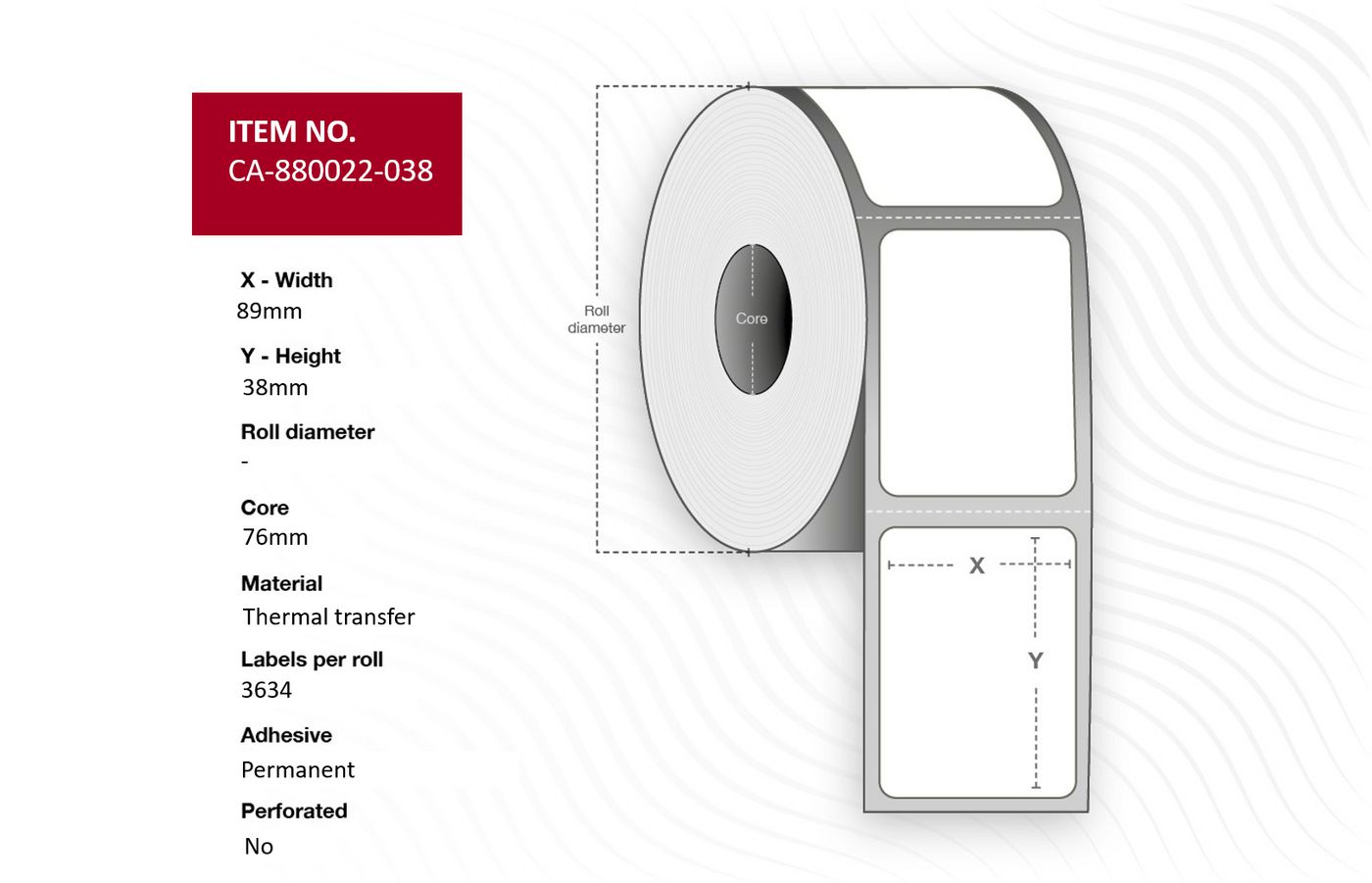

Capture / MPN: CA-880022-038

89 x 38mm, Core 76mm. Thermal

4 811 ₴

Canon / MPN: 2164C002

CRG 047 Toner

4 262 ₴

Canon / MPN: RM1-1313-000

DUPLEXING ASSEMBLY

2 159 ₴

Canon / MPN: CY3-2229-000

FOCUSING, SET

5 514 ₴

Canon / MPN: FM1-H934-010

KEY TOP PCB ASSEMBLY

2 650 ₴